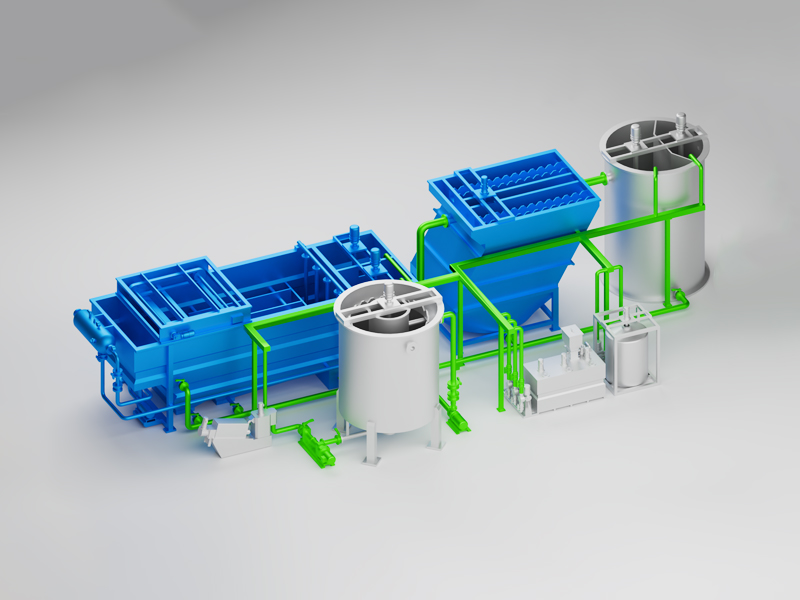

Process Overview

The combination of sedimentation and dissolved air flotation (DAF) is a classic and proven water treatment process.

After pH adjustment (if required), coagulation, and flocculation,

the influent enters the high-efficiency Lamella Clarifier, where heavier suspended solids are removed.

Lighter suspended solids and colloids are then separated in the high-speed Dissolved Air Flotation (RF-DAF) system.

Depending on water quality, an additional coagulation–flocculation stage may be applied before flotation.

This integrated process ensures efficient removal of both heavy and light suspended solids and colloidal matter,

resulting in stable system performance and reliable protection for downstream processes.