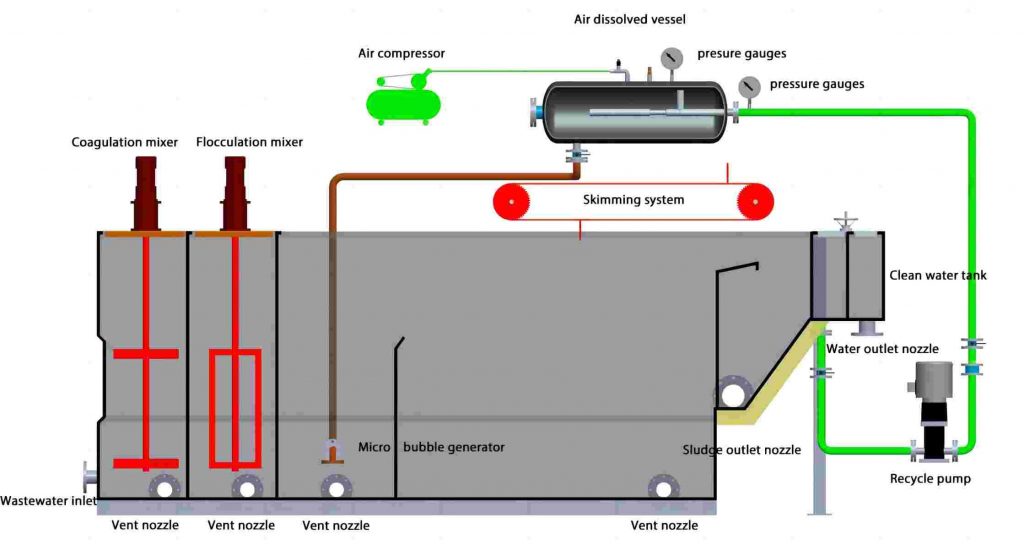

DAF systems are designed to remove total suspended solids (TSS), biochemical oxygen demand (BOD), and oils and greases (O&G) from a wastewater stream.The air flotation process is an effective and fast method of separating solid particles from water and wastewater. Its working principle is that part of the treated waste water circulates into the air-dissolving tank. Under the state of pressurized air, the air is supersaturated and dissolved, and then mixed with the raw water added with flocculant at the entrance of the air flotation tank. Due to the pressure reduction, the supersaturated The air is released, forming tiny bubbles, which quickly attach to the suspended matter and lift it to the surface of the air flotation pool. This creates a sludge slick which is easily removed, and heavier solids settle to the bottom of the tank and are also removed.

DAF system Scope of application:

Paper industry, municipal sewage, chemical industry, beverage industry, printing and dyeing industry, oil refining industry, electroplating industry, food industry, textile industry, slaughtering industry, leather industry, dairy industry, etc., involving the application of suspension matter separation, oil and water separation and purification, coagulation reaction flocculation separation, activated sludge separation and other aspects.

Characteristic of DAF system:

- Large processing capacity, high efficiency and less land footprint.

- The process and equipment structure are simple, easy to use and maintain.

- It can eliminate sludge expansion.

- Aeration to the water when floating, which has an obvious effect on removing the surfactant and odor in the water. At the same time, the aeration increases the dissolved oxygen in the water, which provides favorable conditions for the subsequent treatment.

- For low temperature, low turbidity and water sources containing more algae, the gas float method can be achieved effectively.

- The adsorption of microbubbles and suspended particles improves the removal effect of SS.

- It can effectively remove grease, glue, suspended particles and fibers in sewage, reduce the sewage load of COD, BOD and SS in sewage, and significantly change the color of water quality.

Daf system is widely used in wastewater treatment, mainly used for natural precipitation of emulsified oil and difficult to remove, and suspended solids with relative density close to 1. The applicable wastewater includes oil-containing wastewater, paper-making wastewater, dyeing wastewater, electroplating wastewater, etc., and can also be used for the concentration of the remaining sludge. Here’s to introduce its application in wastewater treatment.

1.Treatment of oily wastewater

The scope of oily wastewater is very wide, petrochemical, mechanical processing, food processing and other industries will produce a large number of oily wastewater. Oil and gas float method is mainly used to remove the emulsified oils.

2.Treatment of printing and dyeing wastewater

Printing and dyeing wastewater has high color color and complex water quality. The ratio of BOD5 / COD is relatively low, so the printing and dyeing wastewater can be treated by air and float method. For the printing and dyeing wastewater containing sulfide and dispersed insoluble dyes, the effect of applying gas float method is remarkable.

3.Treatment of papermaking wastewater

Paper making industry is one of the industries with large water consumption, among which the white water produced by paper copying section accounts for about half of the displacement of the whole paper making process. Paper white water contains a large number of fiber, filler, rosin gum, etc., using gas floating machine to treat white water, not only can recover fiber, improve the utilization rate of resources, but also can make white water recycling, save water resources, reduce the discharge of waste water. According to the actual operation experience, the treatment of white water by air float is generally only 15~20min, with a short time, the removal rate of suspended matter is more than 90%, the removal rate of COD is about 80%, and the concentration of float residue is more than 5%.

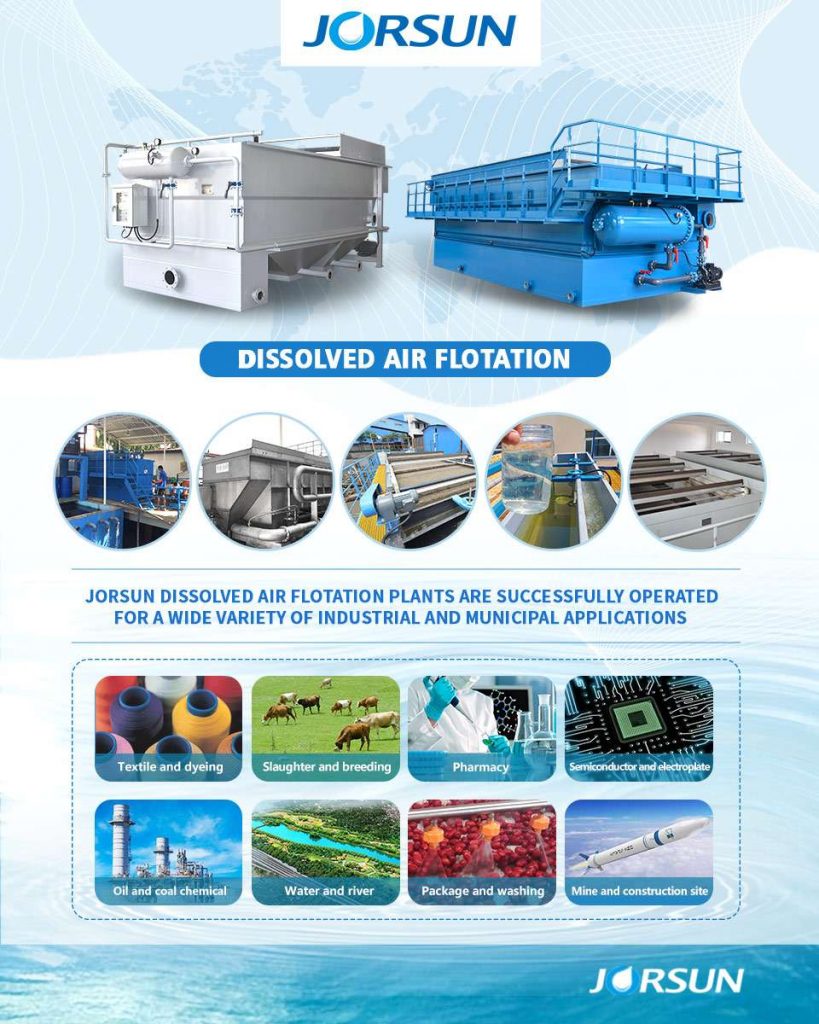

JORSUN Dissolved Air Flotation Plants are successfully operated for a wide variety of industrial and municipal applications, such as:

B- Beverage; Biological effluent;

D- Dairy (milk,ice cream,yogurt etc);

E- Electrinic;

F- Farm; Food(noodle,cookie,bread ,starch,sauce,flavours and fragrances etc);

L- Leachate

M- Meat processing(chicken,beef etc) ; Mine; Municiple;

O- Oil refinery;

P- Package (fruit,shrimp,food etc); Painting; Paper; Pharmacy;

R- River; Rubber glove;

S- Semiconductor; Slaughter; Steel;

T- Textile and dyeing;

U- Underground water;

W- Washing wastewater(plastic,workshop,car,container etc) ;